Microstructure and Crystallographic Orientation Effect on the Mechanical Behavior of Materials

Published:

A key part of materials science is to build the structure-property linkage. For example, mechanical behavior of structural materials depends strongly on the microstructure and orientation of crystalline domains. A deeper understanding of this particular linkage requires a thorough investigation into the generation and motion of dislocations, dislocation-dislocation interaction and dislocation-grain boundary interaction. Characterization of the distribution and types of dislocations over a large area has been made possible with electron backscatter diffraction.

The particular type of dislocation that can be quantified using EBSD is the geometrically necessary dislocation (GNDs) which lead to measurable lattice orientation gradient. The generation of GNDs is a direct consequence of the crystal lattice to maintain strain compatibility during non-uniform deformation for polycrystalline materials. Hence, the dislocation density tensor (Nye tensor) can be related to the curl of elastic distortion tensor (the elastic stretch plus the lattice rotation) i.e. the fundamental equation of continuum dislocation theory. In crystals with high symmetry, the solution to the dislocation tensor is a non-uniqueness problem, meaning that many different configurations of dislocations can simultaneously satisfy the geometrical constraint imposed by the fundamental equation. Therefore, the GND density is obtained with an additional imposed constraint e.g. the total stored energy or dislocation line length. The hot spots of GND density usually correlate to areas of significant geometric constraint e.g. twins, small grains, etc. and high stresses. For materials with inherent anisotropy in microstructure and crystallographic texture, GNDs can be used to study the deformation history and refine the alloy design strategies.

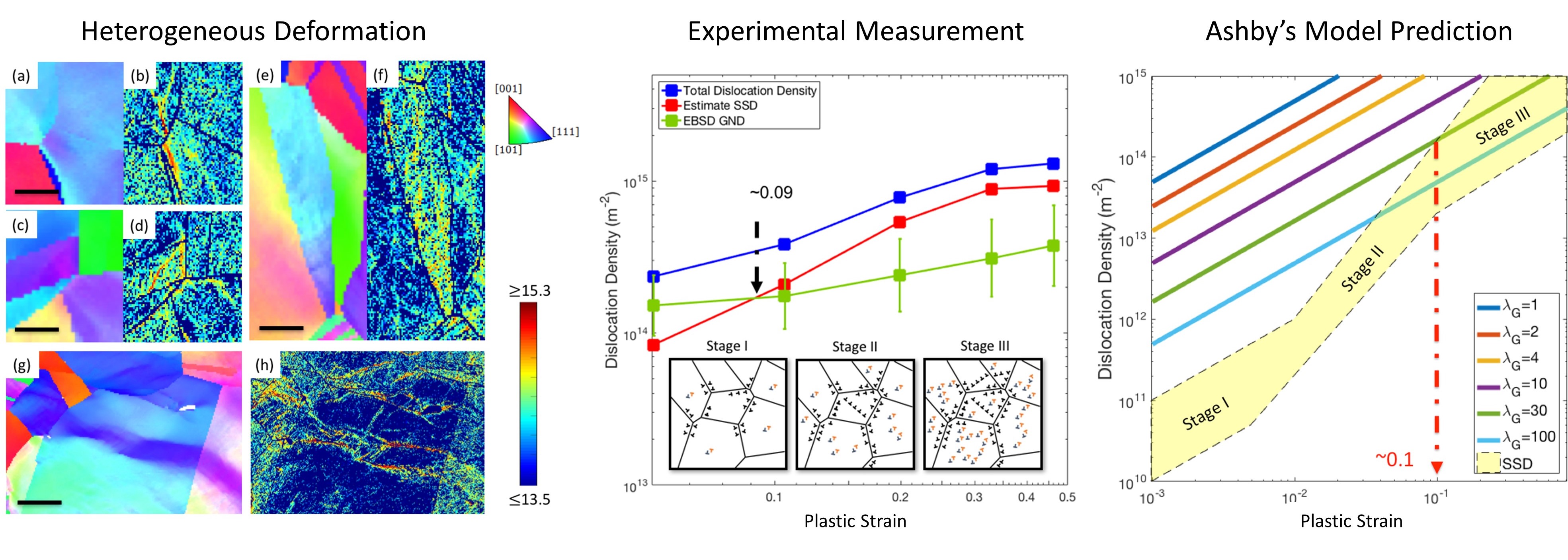

Dislocation-type evolution in quasi-statically compressed polycrystalline nickel

The nature of dislocation generation as a function of applied plastic strain in quasi-statically compressed polycrystalline pure nickel has been studied experimentally at ambient temperature. First, to ensure representative datasets of the geometrically-necessary dislocation densities (ρGND) associated with non-uniform plastic deformation, measurements over large (several millimeter square) areas were made using Hough-based EBSD methods. In addition, the total dislocation density (ρT) responsible for the overall work hardening is estimated from the measured flow stress based on Taylor's hardening model. Next, the statistically stored dislocation (SSD) density (ρSSD) is calculated by subtracting the GND density from the total dislocation density. The results demonstrate that in quasi-statically deformed nickel: i) the measured GND density varies linearly as a function of plastic strain in the range between 0.05 and 0.46; although Ashby's model predicts linearity for GND density evolution over entire range of strains, this study does not cover strains below 0.05; ii) the SSD density increases at a rate much faster than GND density; and iii) the SSD density exceeds the GND density at above 0.09 plastic strain. Both i) and ii) are in agreement with Ashby's prediction, while the magnitudes of GND density (iii) differ from Ashby's model prediction, particularly at large applied strains. Overall, this study enables the interplay of GNDs and SSDs in the hardening of nickel to be gleaned in a quantitative sense. This study illustrates that GNDs are the more important for the strength of polycrystalline metals in the early stages of work hardening, whereas SSDs contribute more to the strength at larger strains. Over the range of strain in this study, work hardening is predominantly through rapid multiplication of SSDs; whereas the GND density is initially higher than SSD density at 0.05 probably due to non-linear evolution of GNDs at low strains (less than 0.05), which will be the subject of future investigation.

Reference: Zhu, C., Harrington, T., Gray III, G.T. and Vecchio, K.S., 2018. Dislocation-type evolution in quasi-statically compressed polycrystalline nickel. Acta Materialia, 155, pp.104-116.

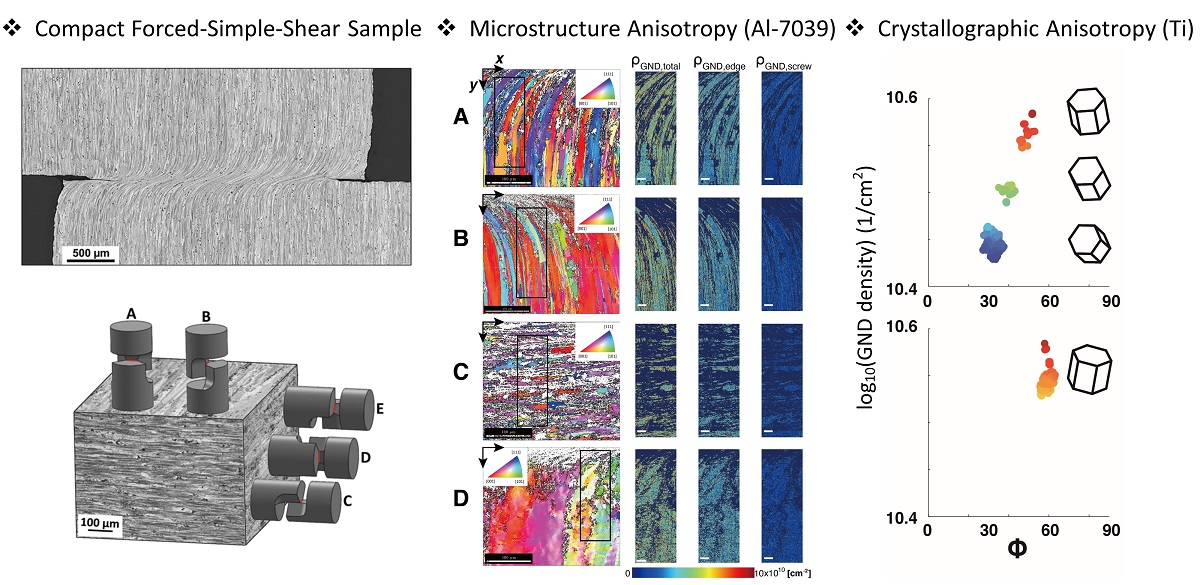

Investigation of the shear response and geometrically necessary dislocation densities in shear localization in high-purity titanium

The influence of microstructural anisotropy on shear response of high-purity titanium was studied using the compact forced-simple-shear specimen (CFSS) loaded under quasi-static loading conditions. Post-mortem characterization reveals significant difference in shear response of different directions in the same material due to material crystallographic texture anisotropy. Shear bands are narrower in specimens in which the shear zone is aligned along the direction with a strong {0001} basal texture. Twinning was identified as an active mechanism to accommodate strains in the shear region in both orientations. This study confirms the applicability of the CFSS design for the investigation of differences in the shear response of materials as a function of process-induced crystallographic texture. A detailed, systematic approach to quantifying shear band evolution by evaluating geometrically necessary dislocations (GND) associated with crystallographic anisotropy is presented. The results show that: i) line average GND density profiles, for Ti samples that possess a uniform equiaxed-grain structure, but with strong crystallographic anisotropy, exhibit significant differences in GND density close to the shear band center; ii) GND profiles decrease steadily away from the shear band as the plastic strain diminishes, in agreement with Ashby's theory of work hardening, where the higher GND density in the through-thickness (TT) orientation is a result of restricted a-type slip in the shear band compared with in-plane (IP) samples; iii) the anisotropy in deformation response is derived from initial crystallographic texture of the materials, where GND density of a-type GNDs are higher adjacent to the shear band in the through-thickness sample oriented away from easy slip, but the density of c+a type GNDs are very similar in these two samples; and iv) the increase in grain average GND density was determined to have strong correlation to an increase in the Euler angle of the grain average orientation, indicating an increased misorientation angle evolution.

Reference: Zhu, C., Livescu, V., Harrington, T., Dippo, O., Gray III, G.T. and Vecchio, K.S., 2017. Investigation of the shear response and geometrically necessary dislocation densities in shear localization in high-purity titanium. International Journal of Plasticity, 92, pp.148-163.

Determination of geometrically necessary dislocations in large shear strain localization in aluminum

In this paper, a systematic approach is presented to quantifying shear band evolution by quantifying geometrically necessary dislocations (GND) associated with morphological anisotropy in 7039-aluminum alloy using the compact forced-simple shear (CFSS) design. A statistically motivated approach, i.e. the line averaged GND density profile, has been developed to investigate the GND density near heavily deformed, shear band regions. Our study shows that: i) line average GND density profiles for the Al samples machined in the A-direction (transverse to pancake-shaped grains), B-direction (parallel to longitudinal pancake-shaped grains, shearing in through-thickness direction), C-direction (parallel to pancake-shaped grains, shearing in the in-plane direction) and D-direction (parallel and through the pancake-shaped grains) are nominally similar; ii) apart from 7039-aluminum alloy C-direction that has a uniform GND distribution in the direction normal to shear due to a grain-sliding mechanism, GND profiles for other samples decrease steadily away from the shear band as plastic strain diminishes, in agreement with Ashby's theory of work hardening, iii) anisotropy in damage evolution and shear-stress shear-strain response of 7039-aluminum alloy is associated with the grain structure of the material, i.e. morphological anisotropy creating variations in grain boundary interactions; iv) microbands formation in D-direction is associated with local GND peaks; v) stress-relief crack propagating along grain boundaries due to the presence of voids or inclusions generates a ‘shielding effect’ on neighboring grains; and vi) the line average GND density profile within a single grain usually varies inversely with the width of the grain for A-, B- and D-directions, leading to generally pronounced higher GND density near triple junctions.

Reference: Zhu, C., Harrington, T., Livescu, V., Gray III, G.T. and Vecchio, K.S., 2016. Determination of geometrically necessary dislocations in large shear strain localization in aluminum. Acta Materialia, 118, pp.383-394.